Effective solution for dual casing abandonment cement barriers

The ProMILL Duo provides an innovative, cost-saving solution for well abandonment applications, where the integrity of the abandonment zone requires the creation of a milled section in two casing sizes. Significant rig time savings are realized when using the ProMILL Duo in comparison to conventional solutions that require a long, inner string casing to be milled.

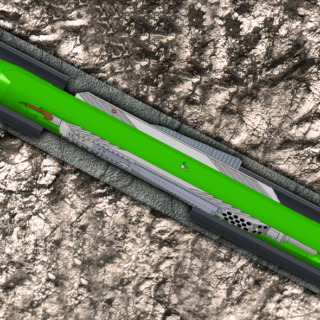

The high expansion ratio of the ProMILL Duo Section Mill allows it to drift through the inner casing in the retracted state and, upon actuation, open up to a larger diameter to mill the outer casing and the coupling.

Dual Casing Milling

System Solution

Providing a more

cost-effective method compared to conventional techniques.

The ProMILL Duo expansion mechanism is based on a proven spline-based actuation platform with a long history of durability and performance. Similarly, the cutting structure on the arms is dressed with WavEdge* ridged milling elements that have demonstrated performance in the ProMILL system.

The system also includes an active stabilization module that optimizes the dynamic behavior and reduces the vibration of the BHA during operation.

The enlargement of the borehole to enable a rock-to-rock barrier is accomplished by using the ProMILL Underreamer (PMUR). The PMUR provides a market-leading expansion ratio and is designed specifically for well-abandonment applications. It incorporates a robust cutter arm mechanism and the latest cutter technology to optimize performance.

Document Downloads

| Title | Link |

|---|---|

| 8200 K-Mill P&A Intervention Performance Bulletin | |

| K-Mill Section Milling Offshore Qatar Performance Bulletin | |

| Red Baron Catalog | |

| Pilot Mill_Brunei_APAC_Performance Bulletin | |

| Patch Installation_ESSA_ N Sea Performance Bulletin | |

| ProMILL 9.625Casing_ESSA_Norway Performance Bulletin | |

| K Mill SectMill LAM_Colombia Performance Bulletin | |

| ProMILL Duo_ESSA_N Germany_Performance Bulletin | |

| ProMILL Duo 6000_MENA_Qatar Performance Bulletin | |

| ProMILL Duo_APAC_Brunei Performance Bulletin | |

| TruEdge_ESSA_NorthSea Performance Bulletin | |

| TruEdge_ESSA_Netherlands Performance Bulletin | |

| TruEdge Milling Cutting_Qatar_MENA Performance Bulletin | |

| TruEdge Milling & Cutting in Qatar – Performance Bulletin | |

| Villavicencio Colombia Facility – SPN | |

| Villavicencio_Colombia Facility | |

| TruEdge News Release RUS | |

| ProMILL Duo Brunei Case Study | |

| ProMILL Duo E Malaysia Case Study | |

| Dunlin N Sea – ProMill – Technical Article | |

| ProMill_Factsheet | |

| Casing Mill Factsheet | |

| ProMILL Duo Factsheet | |

| ProMILL Underreamer Factsheet | |

| WIS ProMILL Duo News Release PRG | |

| WIS ProMill Duo News Release SPN | |

| TruEdge News Release | |

| TruEdge News Release PRG | |

| TruEdge News Release SPN | |

| Well Abandonment Brochure |

Benefits

- As part of the comprehensive plug and abandonment systems portfolio, the ProMILL Duo greatly improves efficiency and reduces cost in a dual string application by eliminating the need to mill up the inner string from the surface or top of cement, when a section needs to be milled in the outer casing for setting a cement plug.

- Multiple trips to mill up the inner casing are eliminated, due to the small drift of this tool and the high expansion ratio.

- A High Ratio Underreamer can be run in the same trip as ProMILL Duo.